Nuria Garcia

Introduction

The use of membrane separation processes allows concentration and fractionation of whey components to obtain valuable ingredients for food and other applications. Manufacturers employ several different membrane separation techniques including ultrafiltration (UF), microfiltration (MF), nanofiltration (NF), and reverse osmosis (RO), to separate out the different components of whey and create whey products to the exact specifications of the end user16.

Different whey products such as whey powder, whey protein concentrate (WPC), whey protein isolate (WPI), whey protein fractions, whey protein hydrolysate, reduced-lactose whey, and demineralized or reduced-mineral whey, are achieved by varying protein, mineral, and lactose levels, as well as various functional properties20 . The product’s value increases with protein concentration. The main difference between MF, UF, NF and RO membranes is their selectivity.

The retention factor (Rf) is a measure of the membrane’s ability to separate components of the feed solution as it reflects the membrane selectivity25. The pore size (determined by the structure of the membrane material) will define which molecules are retained and which molecules flow right through. As the molecular cut-off is lower the operating pressure needed is greater.

The membranes consist of semi-permeable polymeric or ceramic materials. Inorganic ceramic tubular membranes have great pore size uniformity and good selectivity and are very resistant to temperature and chemicals25. They are also easy to clean, and their lifetime is over 10 years, however, their cost is 3-10 times more than organic spiral-wound polymeric membranes, come in a limited range of pore sizes, and are normally only used for microfiltration and in some cases ultrafiltration processes10.

Spiral-wound polymeric membranes consist of several layers of membrane materials rolled around a permeate tube and is one of the most common materials because of larger surface area, limited floor space, high packing density, high permeate flows and lower replacement cost. Some of the disadvantages are limited life, susceptible to fouling, difficult cleaning, extensive pretreatment required, less suitable for viscous feed solutions, limited pH and temperature tolerances for cleaning and operating25.

The problem of fouling

The ideal separation conditions would be continuous flow of the liquid at the applied pressure. However, membrane performance is compromised by fouling or the buildup of adsorbed macromolecules, gels and deposited particles on or in the membrane surface, which cause concentration polarization, and affects membrane selectivity. To control fouling, and reduce the problem of pore blocking, filtration is run at increased cross-flow velocities and low trans membrane pressure24.

Fouling is one critical issue in membrane filtration technology, especially in polymeric membranes that are relatively hydrophobic and facilitate protein adhesion when compared with ceramic membranes2. Fouling in general has a significantly detrimental effect on the efficiency of the separation processes causing flux decline, pressure drop, increased pumping energy required (and associated cost), reduced membrane lifetime, inconsistent product composition and quality.

Whey is the liquid by-product of cheese making and casein manufacturing processes and it is composed mainly by water (93g/100g), lactose and whey proteins. Whey concentration by reverse osmosis (RO) is frequently used to reduce volumes and increase solids content prior to transportation or further processing. RO consist of a pressure-driven membrane separation technique in which a membrane which has pore sizes less than 0.001 micron is employed to separate different components in a fluid mixture.

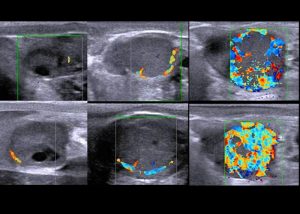

Biofouling, or the buildup of suspended particles is one of the critical issues in membrane filtration technology22, as it has a significantly detrimental effect on the efficiency of the separation processes causing flux decline, pressure drop, reduced membrane lifetime, and inconsistent product composition and quality. Biofilms play a major role in biofouling, but in the dairy environment, the main area of concern is the proliferation of pathogenic bacteria in biofilms, which contribute to product contamination with potentially pathogenic bacteria and possible threat to public health.

The composition and texture of the membrane surface is going to have an impact on bacterial initial attachment. Factors that can affect the development of biofilms are a source of utilizable carbon, temperature, production of exopolysaccharides, inefficient cleaning and disinfection, and the hydrodynamics of the fluid distribution system8.

The problem of biofilms on filtration membranes

Through the nature, bacteria thrive predominantly in multicellular communities or biofilms attached to surfaces and embedded in a self-produced matrix of extracellular polymeric substances28 (EPS). This is a non-trivial lifestyle choice and it has great consequences for cell physiology and survival24. In many industrial and domestic domains biofilms are detrimental, causing corrosion, pipe blockages, equipment failures, unpleasant appearance and odors, product spoilage and infections, resulting in heavy costs of cleaning and maintenance9. Biofilms play a major role in membrane biofouling and contribute to product contamination with potentially pathogenic bacteria and possible threat to public health. To restore flux membrane processes have to be stopped after being running continuously for at least 20 hours, and cleaning in place (CIP) is applied.

Biofilms are well known for resistance to cleaning agents and biocides. Within biofilms, the bacteria cells that are located in the deeper layers are protected from toxic substances and have a better access to nutrients. The pervasiveness and importance of biofilms have driven considerable research efforts in trying to develop materials that prevent bacterial adhesion in addition to new cleaning agents or strategies to remove the existing persistent biofilms.

Our knowledge on the structure of biofilms and their formation has extended remarkably in the last decade, but even after all the molecular and genetic mechanisms and mathematical models that have been studied in detail3, many industries struggle with the eradication of this problem. In dairy filtration systems, some questions remained to be addressed:

- whether using starter cultures that produce exopolysaccharides during cheese making, would enhance the formation of biofilms in the whey processing membranes due to the presence of these polymers that would act as a “glue”.

- whether the exopolymeric substances (EPS) produced by the organisms that are typically living in those membranes would have an effect on the initial attachment of the cells to the membrane or rather they support the cell-cell cohesion or both.

- whether there could be a strategy to reduce biofilm formation on dairy filtration membranes targeting the bacterial EPS that holds cells together.

The structure of a biofilm is not uniform in time or space28. It is important to study the interactions between bacteria and the surfaces in a specific food-processing environment to provide more effective measures for prevention of biofilm formation and for its removal29. Understanding the mechanism of bacterial attachment is fundamental in the development of antifouling technologies for membrane systems.

Mechanisms of bacterial adhesion

The conditioning layer is the foundation on which a biofilm grows. Attachment of a cell to a substrate is termed adhesion, and cell-to-cell attachment is termed cohesion. The mechanisms behind these forms of attachment, ultimately determine the adhesive and cohesive properties a biofilm will exhibit9. Adhesion refers to the state in which two dissimilar bodies are held together by intimate interfacial contact such that mechanical force or work can be transferred across the interface30. The interfacial forces holding the two phases together can be van der Waals forces, chemical bonding or electrostatic attraction.

Biofilms are initiated when bacterial cells attach to a surface and they develop into different stages of maturation as bacteria grow23. The first phase of bacterial adhesion involves physicochemical interactions, after which molecular and cellular interactions take place26. Multiple factors influence the adhesion of cells to a substratum including environmental factors such as nutrients availability, flow conditions or surface characteristics of microorganisms and substratum21.

Cell/substrate surface characteristics

In the initial attachment of bacterial cells to surfaces certain physicochemical interactions between their surfaces and the substratum occur, which are described by the extended Derjaguin, Landau, Verwey, and Overbeek theory27. Such forces include Lifshitz-van der Waal’s, acid/base, and electrostatic interactions.

It has been observed that hydrophobic cells adhere to a greater extent than hydrophilic cells to polystyrene disks on a rotary shaker27. It was first noted that the extent of microbial colonization appears to increase as the surface roughness increases, because on rough surfaces the surface area is greater and the attached cells are protected from the shear forces, having more time for the initial attachment4. For biomaterials consideration should be given to basic surface characterization, such as surface roughness, physical configuration, hydrophobicity, or even chemical composition1.

There are evidences that show that microbial adhesion strongly depends on the hydrophobic-hydrophilic properties of the interacting surfaces17. Now it is commonly recognized that membranes with smooth, hydrophilic, and electrically neutral surfaces are less prone to biofouling than rough, hydrophobic, and charged surfaces18. Membrane manufacturers apply coatings of hydrophilic materials to the surface of membranes to reduce biofouling. Polyamide RO membrane has a contact angle of 55 ± 1.8 at neutral pH13 and is coated to increase the surface hydrophilicity, however, Hassan et al. observed that less than 50% of the surface of a new membrane was covered by this hydrophilic layer11.

The physical appendages of some bacteria (flagella, fimbriae and pili) may stimulate irreversible adhesion to a surface5. Other non-piliated bacteria express adhesins on the cell wall which play a role in host-microbe colonization15.

Biopolymers as adhesives

Some Gram-positive and Gram-negative bacteria can produce biopolymers as capsules and slime layers, which form the glycocalyx. Capsule is a well-defined polysaccharide layer attached to the cells, while slime layer is la unorganized layer of polysaccharides located outside the bacteria cells. The presence of these two structures is not exclusive19.

Biofilms are composed primarily of microbial cells and EPS. After the first attachment, a strengthening of the bonds occurs often involving the formation of polymer bridges between the organism and the surface. These sticky polymers form the matrix network, providing mechanical stability to the biofilm9. EPS account for 50-90% of the total organic carbon of biofilms6. Scientists have found that the EPS in biofilms are composed by exopolysaccharides, glycoproteins, glycolipids and e-DNA7.

Seven categories of EPS have been proposed: structural, sorptive, surface-active, active, informative, redox-active and nutritive EPS7.

- Structural EPS are neutral polysaccharides that act as architectural component in the matrix, facilitates retention of water and nutrients, and provides protection.

- Sorptive EPS are charged polymers that attach to other charged molecules involved in cell–surface interactions.

- Surface-active EPS are molecules with an amphiphilic behavior that have different chemical structures and surface properties. These molecules are involved in biofilm formation and some of them have antibacterial or antifungal properties.

- The active EPS group includes extracellular proteins and enzymes required for biofilm formation and architecture.

Adhesives are substances that act as bridges between surfaces and help them to stick together. For a strong adhesive bond, the establishment of intimate molecular contact is necessary. An ideal adhesive will have a contact angle of zero or near zero, low viscosity (a few centipoises) and is able to spread over the surface and assist in the displacement of trapped air and other particles that may be present14. Adhesive secretions are produced in aquatic and terrestrial live organisms with different functions. The large diversity of these adhesive biopolymers and their significant complexity makes their characterization a difficult task, and often a combination of classical chemical and molecular techniques is needed12.

Application

The formation of microbial biofilms in dairy processing equipment is an unavoidable phenomenon that continues to challenge manufacturers and presents quality and safety issues. Decades of extensive research on biofilms performed under specific conditions have been done, however often the conclusions cannot be generalized due to the heterogeneity of the different environments. Control strategies depend on the nature of the microorganisms on a particular environment and the peculiarity of the surfaces that hold the biofilms.

References

- An, Y. H. and R. J. Friedman. 1997. Laboratory methods for studies of bacterial adhesion. J Microbiol Methods. 30:141-152.

- Baruah, G. L., A. Nayak, and G. Belfort. 2006. Scale-up from laboratory microfiltration to a ceramic pilot plant: Design and performance. Journal of Membrane Science. 274:56-63.

- Blaschek, H. P., H. H. Wang, and M. E. Agle. 2007. Biofilms in the food environment. Blackwell Publishing Professional.

- Characklis, W. G. 1990. Physiological ecology in biofilm systems. in Method Enzymol. W. G. Characklis and K. C. Marshall, ed. John Wiley & sons, New York.

- De Weger, L. A., C. I. van der Vlugt, A. H. Wijfjes, P. A. Bakker, B. Schippers, and B. Lugtenberg. 1987. Flagella of a plant-growth-stimulating Pseudomonas fluorescens strain are required for colonization of potato roots. Journal of Bacteriology. 169:2769-2773.

- Flemming, H.-C., J. Wingender, Griegbe, and C. Mayer. 2000. Physico-chemical properties of biofilms. Pages 19–34 in Biofilms: recent advances in their study and control. E. L.V., ed. Harwood Academic Publishers, Amsterdam.

- Flemming, H. C., T. R. Neu, and D. J. Wozniak. 2007. The EPS matrix: the “house of biofilm cells”. Journal of Bacteriology. 189:7945-7947.

- Florjanic, M. and J. Kristl. 2011. The control of biofilm formation by hydrodynamics of purified water in industrial distribution system. Int. J. Pharm. 405:16-22.

- Garrett, T. R., M. Bhakoo, and Z. B. Zhang. 2008. Bacterial adhesion and biofilms on surfaces. Prog. Nat. Sci. 18:1049-1056.

- 2012. Membrane Filtration in the Dairy Industry. Hanby.

- Hassan, A. N., S. Anand, and M. Avadhanula. 2010. Microscopic observation of multispecies biofilm of various structures on whey concentration membranes. Journal of Dairy Science. 93:2321-2329.

- Hennebert, E., B. Maldonado, P. Ladurner, P. Flammang, and R. Santos. 2015. Experimental strategies for the identification and characterization of adhesive proteins in animals: A review. Interface focus 5:20140064.

- Hurwitz, G., G. R. Guillen, and E. M. V. Hoek. 2010. Probing polyamide membrane surface charge, zeta potential, wettability, and hydrophilicity with contact angle measurements. Journal of Membrane Science. 349:349-357.

- Kinloch, A. J. 1987. Adhesion and Adhesives: Science and Technology. Springer Science & Business Media.

- Kline, K. A., S. Falker, S. Dahlberg, S. Normark, and B. Henriques-Normark. 2009. Bacterial adhesins in host-microbe interactions. Cell host & microbe 5(6):580-592.

- Kumar, P., N. Sharma, R. Ranjan, S. Kumar, Z. F. Bhat, and D. K. Jeong. 2013. Perspective of membrane technology in dairy industry: A review. Asian-Australas J. Anim Sci. 26:1347-1358.

- Liu, Y., S. F. Yang, Y. Li, H. Xu, L. Qin, and J. H. Tay. 2004. The influence of cell and substratum surface hydrophobicities on microbial attachment. Journal of Biotechnology. 110:251-256.

- Mansouri, J., S. Harrisson, and V. Chen. 2010. Strategies for controlling biofouling in membrane filtration systems: challenges and opportunities. J. Mater Chem. 20:4567-4586.

- Mesnage, S., E. Tosi-Couture, P. Gounon, M. Mock, and A. Fouet. 1998. The capsule and S-layer: two independent and yet compatible macromolecular structures in Bacillus anthracis. Journal of bacteriology 180:52-58.

- Mollea, C., L. Marmo, and F. Bosco. 2013. Valorisation of Cheese Whey, a By-Product from the Dairy Industry. in Food Industry. I. Muzzalupo, ed. InTech open science, http://dx.doi.org/10.5772/53159

- Palmer, J., S. Flint, and J. Brooks. 2007. Bacterial cell attachment, the beginning of a biofilm. J. Ind. Microbiol. Biot. 34:577-588.

- Peinemann, K.-V. a. P. N., S. 2010. Membranes for Water Treatment: Volume 4.

- Ridgway, H., K. Ishida, G. Rodriguez, J. Safarik, T. Knoell, and R. Bold. 1999. Biofouling of membranes: Membrane preparation, characterization, and analysis of bacterial adhesion. Biofilms 310:463-494.

- Romeo, T. 2008. Bacterial Biofilms.

- Tamime, A. Y. 2012. Membrane Processing: Dairy and Beverage Applications. Society of Dairy Technology Series. Wiley-Blackwell, Chichester, West Sussex, UK.

- Vadillo-Rodriguez, V., H. J. Busscher, H. C. van der Mei, J. de Vries, and W. Norde. Role of lactobacillus cell surface hydrophobicity as probed by AFM in adhesion to surfaces at low and high ionic strength. Colloid Surface. 41:33-41.

- van Loosdrecht, M. C., J. Lyklema, W. Norde, and A. J. Zehnder. Bacterial adhesion: A physicochemical approach. Microbial Ecology 17:1-15.

- G., C. and K. C. Marshall. 2001. Biofilms. Vol. 1. Wiley.

- Wong, A. C. 1998. Biofilms in food processing environments. Journal of dairy Science. 81:2765-2770.

- Wu, S. 1982. Polymer interface and adhesion. MARCEL DELKER, Inc., Wilmington, Delaware.