Carlos Moroni & Fernando Diaz

Corn grain is one of the most used energy ingredients for feeding dairy cattle. One method of storing corn grain is in its wet form (25 to 35% moisture, 28% being the optimum level). The storage of corn grain with high moisture has operational advantages such as early harvesting, reduction of losses during harvesting and reduction of transportation and drying costs. In addition, from a nutritional point of view, this preservation method increases rumen degradability of starch.

A recent work (da Silva et al., 2018) evaluated the effects of an inoculant application (Lactobacillus buchnerii) and storage time on ruminal degradability, aerobic stability, and chemical and microbiological composition of high moisture corn. After harvesting, high moisture corn was rolled (average particle size of 4.27 mm) and treated with 2 ml of chlorine-free water/kg with or without the inclusion of an L. buchnerii inoculant (1 × 105 ufc /g).

Table 1 shows chemical composition, pH and microbial count of wet corn grain prior to fermentation. It can be observed that the two lots were similar. After ensiling, samples were taken from each treatment after 15, 30, 60, 90, 120, 180, 240 and 300 days of storage.

| Table 1 | Non-inoculated | Inoculated |

| Dry matter (DM; % fresh matter) | 62.1 | 61.3 |

| Crude protein (% DM) | 8.0 | 8.1 |

| Ethanol soluble carbohydrates (% DM) | 13.8 | 13.1 |

| pH | 5.38 | 5.37 |

| Lactic acid bacteria (log cfu/g) | 7.74 | 7.40 |

| Yeasts (log cfu/g) | 5.63 | 5.90 |

These were the main results reported in the study:

- Chemical composition and fermentation products:

Inoculant application and storage length affected dry matter (DM) content, pH, ammonia concentration and lactic acid bacteria count. These parameters were higher in the inoculated high moisture corn. In contrast, prolamin content and yeast count was significantly lower in the inoculated corn. Protein concentration was similar between treatments. In general, DM content increased progressively until 240 days of storage and decreased dramatically thereafter.

Compared to untreated high moisture corn, the inoculated with L.buchnerii showed higher concentrations of ethyl acetate, methanol, iso-butyric acid and 1-propanol, and lower contents of ethyl lactate and iso-valeric acid. In addition, the low concentrations of butyric acid and acetone found in the inoculated corn indicate a lower growth of undesirable microorganisms, since these compounds are typical metabolites of the metabolic pathways of clostridia.

| Table 2 | Non-inoculated | Inoculated |

| Total fermentation products (% DM) | 34.7 | 36.7 |

| Lactic acid (g/kg of DM) | 26.7 | 16.0 |

| Ethanol (g/kg of DM) | 4.35 | 5.33 |

| Acetic acid (g/kg of DM) | 3.13 | 8.99 |

| 2,3-Butanediol (mg/kg of DM) | 148 | 552 |

| Ethyl lactate (mg/kg of DM) | 89.2 | 74.8 |

| Butyric acid (mg/kg of DM) | 54.2 | 3.94 |

| Ethyl acetate (mg/kg of DM) | 48.0 | 84.7 |

| Methanol (mg/kg of DM) | 42.2 | 52.2 |

| 1,2-Propanediol (mg/kg of DM) | 41.4 | 5493 |

| Acetone (mg/kg of DM) | 37.4 | 38.1 |

| Propionic acid (mg/kg of DM) | 14.6 | 14.6 |

| Iso-Valeric acid (mg/kg of DM) | 2.95 | 1.97 |

| Iso- Butyric acid (mg/kg of DM) | 1.73 | 4.05 |

| 1-Propanol (mg/kg of DM) | 0.00 | 3.43 |

- Aerobic Stability:

Aerobic stability gradually increased with storage time, this was possibly due to the gradual accumulation of fermentation products with antifungal properties, such as acetic acid and propionic acid. Furthermore, marked differences appeared between the inoculated and uninoculated product, especially after 60 days of storage.

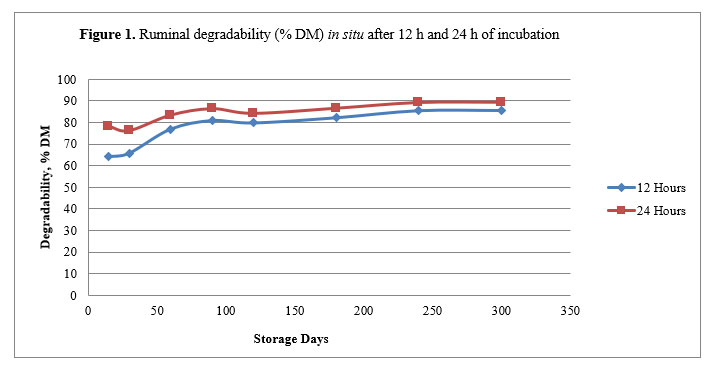

- Starch rumen degradability and proteolysis:

The gradual decrease in prolamin and the consequent increase in ammonia observed throughout storage could be related to proteolytic activity during the fermentation process. While it is not the only factor, degradation of the protein matrix exposes and makes starch granules more digestible.

No effects on DM ruminal degradability were observed between treatments. Figure 1 shows DM degradability after 12 and 24 hours of incubation, which could simulate the degradability in diets with high and low passage rates, respectively. Dry matter ruminal degradability increased 0.3%/day until 71 days of storage. Subsequently, the increase in degradability was ten times slower (0.03%/day).

In conclusion, inoculation with L.buchneri improved nutritional composition and aerobic stability of high-moisture corn. Prolonged storage of the material increased the in situ ruminal degradability of the DM, although the main changes occurred during the first two months of storage. For this reason, to maximize the effects of protein matrix breakdown and increase starch digestibility in high moisture corn, a minimum fermentation period of at least 60 days is recommended.

In conclusion, inoculation with L.buchneri improved nutritional composition and aerobic stability of high-moisture corn. Prolonged storage of the material increased the in situ ruminal degradability of the DM, although the main changes occurred during the first two months of storage. For this reason, to maximize the effects of protein matrix breakdown and increase starch digestibility in high moisture corn, a minimum fermentation period of at least 60 days is recommended.

Reference

Naiara C. da Silva, Cleisy F. Nascimento, Vinícius M.A. Campos, Michele A.P. Alves, Flávio D. Resende, João L.P. Daniel, Gustavo R. Siqueira. 2019. Influence of storage length and inoculation with Lactobacillus buchneri on the fermentation, aerobic stability, and ruminal degradability of high-moisture corn and rehydrated corn grain silage. Animal Feed Science and Technology. 251: 124 – 133.

© 2019 Dairy Knowledge Center, LLC. All Rights Reserved.