María Villagrasa & Fernando Diaz

The US is the world’s leading producer of almonds, with 80% of the total harvest concentrated in California thanks to its adequate climate. In 2020 California almond production was estimated in 1,361 billion tons, which also results in huge volumes of almond hulls, since for every kg of almonds produced two kg of hulls are left behind.

Its use as an animal feed component not only gives value to this co-product but is also in line with the circular economy philosophy by avoiding the loss of byproducts through recycling.

There are several almond varieties (about 30 produced in California alone) classified according to distinctive characteristics such as their size or shape. The Nonpareil variety, for example, has a soft and weak hull, while in the Butte it is semi-hard, whereas in the Mission it is hard.

These differences make the nutritional value of the hull also different. However, while feeding this co-product is commonplace, there are few studies on their nutritional value for dairy cows. More accurate information on the chemical composition of almond hulls would allow to adjust the diet offered to cows and improve their performance.

A group of researchers from the University of California (DePeters et al., 2020) have conducted a study to determine the nutritional composition of the different varieties of almond hulls.

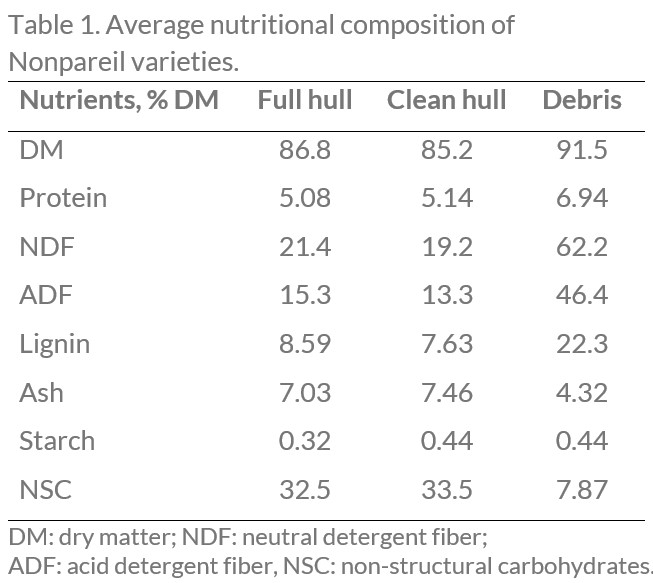

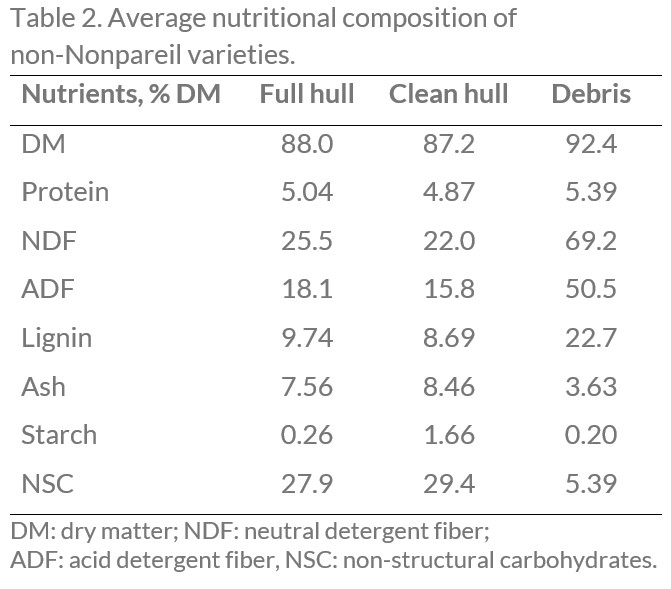

Twelve different samples of common California almond variety hulls were evaluated in this experiment. These samples included: 5 Nonpareil, 2 Butte/Father blend, 1 Butte/Mission blend and 4 that had no variety specification. To simplify the results the varieties were grouped in two: Nonpareil and non-Nonpareil (which included the seven varieties that are not Nonpareil). Tables 1 and 2 show their nutritional composition. In addition, the hulls were processed and divided into three groups:

- full almond hull (with residues: outer sheath, twigs, leaves, etc.)

- clean hull (no debris)

- debris

The proportion of debris in the Nonpareil group was 4.7% while for the non-Nonpareil group 6.8%. The difference between the proportion of debris may vary depending on the growing location of the almonds, which in turn, can affect the nutritional quality of the hulls, so it is important to consider the region where the almond was grown.

From what can be seen from the tables, the DM content was higher for the debris and lower for the entire hulls in both groups. The debris have low moisture content, so when extracted from the entire hull, the DM content of the clean hull decreased for both the Nonpareil group and the non-Nonpareil group.

Fiber concentration varies widely in almond hulls

A summary of the published literature supports the observation that the concentration of fiber in the hulls of this study varied considerably. The average NDF content for the complete hull of the Nonpareil group was 21.4% (between 18.5 and 22.9% DM), while for the non-Nonpareil it was higher (average 25.5%) and more variable (20.4 to 31.7% DM).

With regards to the ADF, the entire hull of the Nonpareil group had 15.3% with a minimum of 13.5 and a maximum of 16.7% DM. The variation in ADF was much greater for the non-Nonpareil group with an average content of 18.1% (between 13.6 and 24.1% DM).

The higher fiber content of the non-Nonpareil group was probably related to a smaller hull size relative to the residues but could also be related to adhesion to the hull from part of the outer sheath.

Concentration of protein and carbohydrates in almond hulls

Protein concentration was low in almond hulls. The protein content of the complete hull was similar in the Nonpareil group (5.08% DM) and in non-Nonpareil (5.04% DM). In fact, waste disposal almost did not change the percentage of protein from the clean hull, although the difference was greater for the non-Nonpareil group (Nonpareil: clean hull: 5.14%; residues: 6.94%; non-Nonpareil: clean shell: 4.87%; residues: 5.39% DM).

The amount of non-structural carbohydrates was lower in residues than in the entire hulls and clean in both groups (Nonpareil: full shell: 32.5%; clean shell: 33.5%; residues: 7.87%; non-Nonpareil: full hull: 27.98; clean hull: 29.4% residues: 5.39% DM).

Conclusions

The main conclusions reached in this study were:

- The almond variety and the amounts of residues influence the nutritional composition of the almond hulls.

- Reducing the proportion of almond hull residues will reduce the fiber content, thus improving its nutritional value for dairy cow

- The Nonpareil variety was superior in quality, measured by a higher sugar content and a lower content of ash, lignin and NDF compared to the other varieties.

The authors believe that it would be necessary to carry out a thorough study to evaluate the variety of almond trees, harvesting and peeling methods, growth region, pruning practices and planting age, all of them factors that probably affect the nutritional value of almond hulls.

Reference

E. J. DePeters, K. L. Swanson, H. M. Bill, J. Asmus, and J. M. Heguy. 2020. Nutritional composition of almond hulls. Applied Animal Science 36:761–770.

© 2021 Dairy Knowledge Center. All Rights Reserved.