Mercedes Gonzalez & Fernando Diaz

Silages contain volatile organic compounds (VOC) that arise from fermentation of organic matter by yeasts and heterofermentative lactic acid bacteria (LAB), enterobacteria or clostridiums, which produce acetic, propionic or butyric acids, and alcohols such as ethanol or propanol. Other VOC are esters and aldehydes. The concentration of VOC in silage varies depending on each forage type, storage conditions and the use of additives.

The VOC present in silages can impart strange smells and result in feed rejection decreasing feed intake, reducing production, and altering cow metabolism.

The composition of corn, grass and sorghum silages can be altered by a delay in sealing (more than 24 hours after filling) and by using additives. Previous studies have shown that the use of sorbic, benzoic or propionic acid salts offer promising results to control VOC production.

In an experimental study, Weia et al (2020) worked on the hypothesis that VOC production, yeast development and dry matter (DM) losses would be affected by delayed silage sealing and the use of fungal inhibitors.

Forage corn was harvested and cut to a length of 10 mm, and then stored in two separate piles; one was left untreated and the other received a mixture of 257 g/l sodium benzoate, 134 g/l potassium sorbate and 57 g/l ammonium propionate, at a dose of 2 ml/kg silage. There were thus four experimental groups:

- CON: Untreated corn silage

- CON Delayed: untreated corn silage, sealed late (>24 hours)

- SA: corn silage treated with additives

- SA delayed: corn silage treated with additives, sealed late (>24 hours)

Chemical analysis included the determination of DM, organic acids, alcohols and esters, pH, and lactic acid. A microbiological study was also conducted to perform yeast and mold counts.

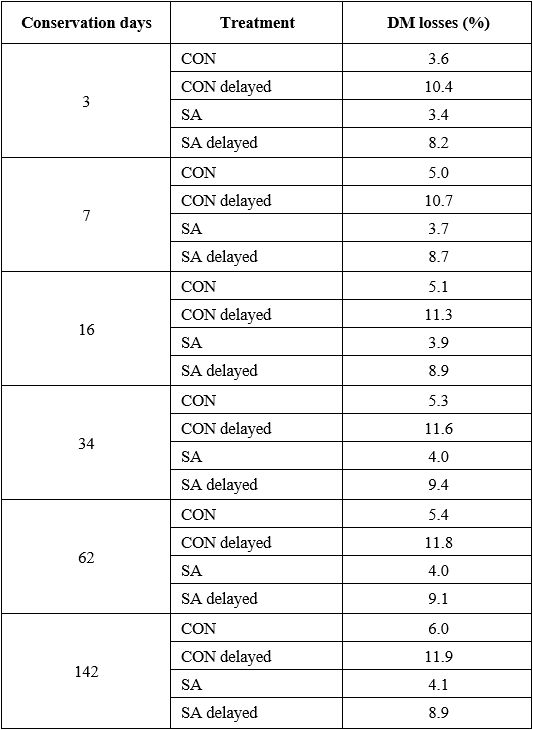

Dry matter losses are used to determine the effectiveness of the fermentation process. In this study, DM losses were higher in the CON delayed and SA delayed groups and the use of additives reduced DM losses, as can be seen in the table.

Corn fermentation is a complex process involving multiple microorganisms that execute a wide range of metabolic pathways. Therefore, the production of organic acids can be very different even if the DM content is similar between silages.

When silage sealing is delayed, lactic acid production is reduced and acetic acid production increases. This could be associated with the selective effect of additives on some acetate-producing microorganisms that may be more active at different stages of the fermentation process.

In this study, CON and SA silages had lower concentrations of ethanol and less DM losses. The development of yeast and the concentration of ethanol, their main metabolic final product, followed a very similar pattern in the early stages of fermentation.

Ethanol was formed quickly mainly stimulated by the delayed sealing, reaching a concentration of more than 0.50 % of DM on day 3 and a maximum of 3.23 % of DM on day 142. Yeasts probably changed their aerobic breathing metabolism to fermentation as soon as the silo was sealed and compacted.

Yeast counts

There were higher yeast counts in silage than in fresh corn until day 7, followed by a decrease during conservation. Silages CON delayed and SA delayed had higher yeast counts than CON and SA between days 3 and 7 of preservation. The use of additives reduced the yeast population, but the effect was greater on silages with CON delayed and SA delayed.

The production of ethyl lactate was persistent throughout the fermentation process, it was however formed very quickly and at high concentrations on day 3 of preservation reaching 0.30 % DM in silages CON delayed. This study found that the increase in ethyl acetate was parallel to that of yeast counts, especially in delayed sealed silages for the first 3 days, because some yeast species synthesize it.

The study concluded that the delay in sealing stimulates yeast growth, with an excess of ethanol production and the formation of ethyl esters of lactic and acetic acids resulting in significant DM losses.

The use of chemical additives with antifungal effects reduces the production of ethanol and VOC, thus reducing silage DM losses regardless of silage preservation conditions.

Reference

Kirsten Weiß, Bärbel Kroschewski, Horst Auerbach. Formation of volatile organic compounds during the fermentation of maize as affected by sealing time and silage additive use. Archives of Animal Nutrition. 2020 Jun; 74(2): 150-163.

© 2020 Dairy Knowledge Center. All Rights Reserved.